Polyurethane Chemicals

Polyurethane Chemicals: Comprehensive Solutions for Every Industry

At Emirachem, we are proud to be your trusted partner for premium polyurethane chemicals, providing a complete range of additives and raw materials used in the manufacturing of flexible and rigid polyurethane foams. Our high-performance product line is designed to deliver superior quality, reliability, and efficiency across diverse industrial applications such as insulation, furniture, automotive, footwear, and packaging.

Whether you’re producing flexible foams, rigid foams, coatings, adhesives, sealants, or elastomers, Emirachem's Polyurethane Chemicals offer tailored solutions to meet your unique production requirements.

Our Polyurethane Chemical Products

🔹 Polyols

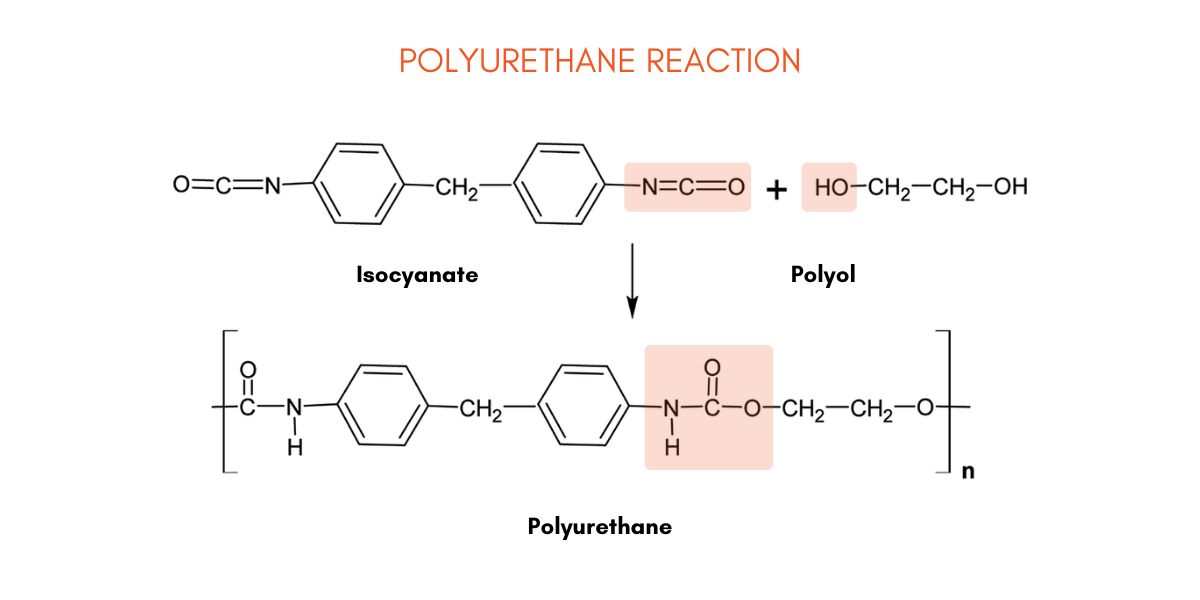

Polyols are key building blocks in polyurethane production, influencing the flexibility, durability, and performance of the end product.

• Polyether Polyols

These polyols are ideal for flexible foam applications due to their excellent hydrolytic stability and processing ease. They offer:

-

High resilience

-

Low viscosity

-

Excellent compatibility with a variety of isocyanates

Used in: Furniture foams, mattresses, car seats, sponges, and packaging foams.

• Polyester Polyols

Polyester polyols offer higher rigidity, abrasion resistance, and chemical resistance. These are well-suited for:

-

Rigid foam applications

-

Shoe soles

-

Coatings & adhesives

-

Flexible molded foams

They are excellent for applications that require higher tensile strength and thermal resistance.

🔹 TDI 80/20 (Toluene Diisocyanate)

A commonly used aromatic isocyanate blend (80% 2,4-TDI and 20% 2,6-TDI), perfect for flexible foam applications. It features:

-

Excellent reactivity with polyether polyols

-

Suitable for high-volume foam production

-

Widely used in flexible slabstock and molded foam

Emirachem supplies top-grade TDI 80/20 ensuring consistency and purity for industrial-scale manufacturing.

🔹 MDI (Methylene Diphenyl Diisocyanate)

MDI is a versatile isocyanate used in both rigid and flexible foams, offering improved insulation and load-bearing properties.

• Monomeric MDI

Pure form used in specialty applications requiring precision and high-performance bonding.

• Polymeric MDI

Blended form ideal for rigid foam, offering:

-

High thermal insulation

-

Good flow properties

• Prepolymeric MDI

Modified MDI with improved workability and extended pot life, used in adhesives, sealants, and elastomers.

🔹 Blowing Agents

Blowing agents are critical for foam expansion. Emirachem supplies both physical and chemical blowing agents that ensure:

-

Uniform cell structure

-

Low thermal conductivity

-

Reduced density and material cost

Used in: Refrigeration insulation, spray foam, and molded foam.

🔹 Amine Catalyst

Essential for the reaction between isocyanate and polyol, our amine catalysts offer:

-

Controlled reaction rates

-

Foam stability

-

Improved surface quality

Applications: Slabstock foams, rigid insulation panels, and molded automotive parts.

🔹 Stannous Octoate

A premier metal-based catalyst, Stannous Octoate accelerates urethane formation and enhances final product quality:

-

Ideal for flexible polyurethane foam production

-

Offers excellent processing control

-

Works synergistically with amine catalysts

🔹 Silicone Surfactant

Silicone surfactants are used to stabilize the cell structure during foam formation.

• For Rigid Foam

-

Improves insulation properties

-

Ensures fine, closed-cell structure

-

Enhances dimensional stability

• For HR Moulded Foam & Viscoelastic Foam

-

Provides excellent flowability

-

Enhances comfort and resilience

-

Offers superior cell uniformity

🔹 Foam Hardener

Foam hardeners enhance foam density and hardness for specialized applications:

-

Used in rigid foam and high-load-bearing foams

-

Helps modify physical properties without altering formulation ratios

🔹 Flame Retardant

Safety is critical in polyurethane applications. Our flame retardants provide:

-

Enhanced fire resistance

-

Compliance with global fire safety standards

-

Suitable for furniture, construction, and automotive foams

🔹 Colorants

Emirachem offers vibrant and stable polyurethane-compatible colorants for customized applications:

-

Available in liquid and paste form

-

UV-resistant, non-bleeding, and heat-stable

-

Used in automotive interiors, footwear, and specialty foams

Polyurethane Applications

1. Fabric & Accessories

Polyurethane-based fabrics and accessories offer superior durability, flexibility, and resistance to abrasion, making them ideal for use in upholstery, automotive interiors, and technical textiles. These products are designed to combine aesthetic appeal with high-performance functionality, ensuring long-lasting quality.

Key Features:

- Exceptional wear resistance

- Water and stain repellency

- Soft-touch finish for premium applications

2. Machinery for Polyurethane Applications

State-of-the-art machinery is essential for efficient and precise polyurethane processing. Our portfolio includes advanced equipment designed for the production of flexible foams, rigid systems, elastomers, and coatings.

Applications:

- Foam manufacturing

- Injection molding

- Spray coating systems

3. Specialties

Our specialty polyurethane chemicals are engineered for niche applications that demand unique performance characteristics. These include high-performance coatings, elastomers, and thermoplastic polyurethanes (TPUs).

Examples:

- Coatings for industrial and automotive use

- Elastomers for seals, gaskets, and belts

- TPU for footwear and technical applications

4. Adhesives

Polyurethane adhesives provide excellent bonding strength, flexibility, and resistance to environmental factors, making them suitable for a wide range of substrates and industries.

Applications:

- Automotive assembly

- Construction bonding

- Footwear manufacturing

5. Integral Skin Foam

Integral skin polyurethane foam combines a durable outer skin with a soft core, providing excellent impact resistance and aesthetic appeal. These foams are widely used in furniture, automotive parts, and industrial components.

Advantages:

- Lightweight yet durable

- High resistance to wear and tear

- Smooth, customizable surface finish

6. Flexible Molded Foams

Flexible molded foams are essential for cushioning applications, offering superior comfort and long-lasting performance. These foams are extensively used in furniture, bedding, and automotive seating.

Key Features:

- Exceptional resilience and support

- Customizable density and firmness

- Excellent breathability

7. Rigid Polyurethane Systems

Rigid polyurethane foams are renowned for their thermal insulation properties, making them indispensable in construction, refrigeration, and HVAC industries.

Benefits:

- High thermal efficiency

- Lightweight and easy to install

- Excellent moisture resistance

8. Castor Oil

Castor oil is a natural and sustainable raw material used in the production of polyurethane systems. Its renewable origin and versatility make it a preferred choice for eco-friendly applications.

Applications:

- Bio-based polyurethane foams

- Industrial lubricants

- Coatings and adhesives

9. Adipic Acid

Adipic acid is a crucial component in the production of polyester polyols, which are used to manufacture high-performance polyurethanes. It ensures superior durability and resistance in end products.

Key Uses:

- Rigid foams

- Flexible foams

- Thermoplastic polyurethanes

10. Colors and Additives

Polyurethane products can be enhanced with a wide range of colors and additives to meet specific functional and aesthetic requirements. These include pigments, UV stabilizers, and flame retardants.

Options Available:

- Custom color matching

- Functional additives for improved performance

- Aesthetic finishes for various applications

Industries We Serve

Our polyurethane chemicals and products cater to a wide array of industries, including:

- Construction: Thermal insulation, sealants, and coatings.

- Automotive: Seating, soundproofing, and adhesives.

- Furniture: Cushions, mattresses, and upholstered products.

- Textiles: Technical fabrics and durable coatings.

- Footwear: Soles, insoles, and adhesives.

- Industrial Applications: Elastomers, gaskets, and machinery components.

💼 Why Choose Emirachem?

At Emirachem, we stand out for delivering not just chemicals but value-added solutions that help your business grow. Here’s what makes us a leader in the polyurethane industry:

-

Authorized Distributor of globally trusted chemical brands

-

Tailored Technical Support and formulation expertise

-

Flexible shipping terms & payment solutions

-

Strict Quality Assurance and fast, responsive service

Partner with Emirachem

At Emirachem, we are committed to empowering your business with high-quality polyurethane chemicals and unparalleled service. Whether you need raw materials, specialty products, or technical support, we have the expertise and resources to help you succeed.

Contact us today to learn more about our polyurethane solutions and discover how we can contribute to your success. Let Emirachem be your trusted partner in delivering excellence and innovation.

📞 Contact Emirachem Today!

Whether you're looking to optimize your existing foam systems or create innovative polyurethane-based products, Emirachem has the right solutions.

Get in touch with us to discover how our high-performance polyurethane chemicals can transform your production capabilities.

📧 info@emirachem.com

Explore our product range and experience the Emirachem advantage!