Microcellular & Integral Skin Polyurethane Foam: Understanding Their Applications and Advantages

Polyurethane is one of the most versatile materials in modern manufacturing, and its adaptability has led to the creation of specialized foam variants like microcellular and integral skin polyurethane foam. These two types of foam have carved out their niches across industries due to their exceptional properties and performance capabilities. In this blog, we’ll explore the science behind microcellular and integral skin polyurethane foam, their key features, applications, and why Emirachem is your go-to supplier for premium polyurethane solutions.

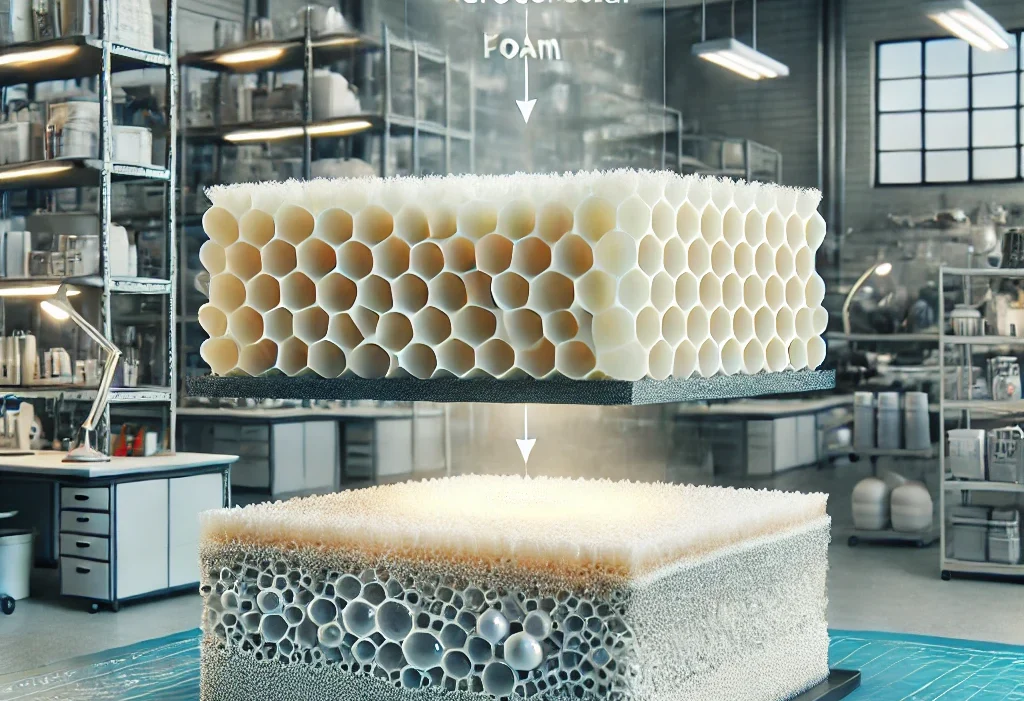

What is Microcellular Polyurethane Foam?

Microcellular polyurethane foam is a specialized material known for its fine cellular structure. The foam contains millions of tiny, uniform cells that offer a combination of flexibility, strength, and low density. This unique structure provides excellent cushioning, impact resistance, and energy absorption.

Key Features of Microcellular Foam

- Lightweight and Durable: The fine cellular structure creates a lightweight foam that is incredibly resilient and durable.

- Energy Absorption: Offers excellent shock and vibration damping, making it ideal for high-impact applications.

- Customization: The density and hardness can be adjusted to meet specific application needs.

- Chemical and Environmental Resistance: Microcellular foam is resistant to oils, chemicals, and weathering, ensuring long-lasting performance.

Applications of Microcellular Foam

Microcellular foam is widely used in industries that demand durability, flexibility, and lightweight materials:

- Automotive: Energy-absorbing components, gaskets, and seals.

- Footwear: Shoe soles and midsoles for cushioning and comfort.

- Industrial: Vibration isolation pads, rollers, and grips.

- Consumer Goods: Sports equipment, protective cases, and packaging materials.

At Emirachem, we provide high-quality raw materials for producing microcellular polyurethane foam that meets the stringent requirements of these industries. Contact us for tailored solutions.

What is Integral Skin Polyurethane Foam?

Integral skin polyurethane foam, also known as self-skinning foam, is a unique type of foam that forms a dense outer skin during the molding process. This outer layer provides a smooth, durable surface, while the inner core remains flexible and lightweight.

Key Features of Integral Skin Foam

- Self-Skinning Properties: Forms a tough outer skin that eliminates the need for additional coatings or coverings.

- Durability: The outer layer offers enhanced resistance to abrasion, wear, and tear.

- Aesthetic Appeal: The smooth, finished surface can be molded into various textures and colors for design flexibility.

- Ergonomic Benefits: Provides soft-touch surfaces and cushioning, making it ideal for consumer-facing products.

Applications of Integral Skin Foam

Integral skin foam is favored in applications where both aesthetics and performance are critical:

- Furniture: Armrests, headrests, and seat cushions.

- Medical: Handles, grips, and cushioning for medical equipment.

- Automotive: Steering wheels, dashboards, and interior trim components.

- Recreational Products: Padded grips for bicycles, gym equipment, and outdoor furniture.

Emirachem offers premium raw materials for producing integral skin polyurethane foam, ensuring that your products deliver both functionality and visual appeal. Reach out to us for expert guidance and top-tier supplies.

How Are These Foams Made?

Both microcellular and integral skin polyurethane foams are produced through the reaction between polyols and isocyanates. The process involves the use of blowing agents that help form the cellular structure. For integral skin foam, the molding process is carefully controlled to create a dense outer skin while maintaining a lightweight core.

Production Parameters

- Blowing Agents: Determine cell size and density.

- Mold Design: Plays a critical role in shaping the foam and forming the outer skin.

- Additives: Enhance properties like UV resistance, flame retardancy, and color.

Emirachem supplies high-quality polyols, isocyanates, and additives to optimize the production of both types of foam. Whether you’re producing lightweight automotive components or ergonomic furniture, we have the materials you need.

Comparing Microcellular and Integral Skin Foam

| Feature | Microcellular Foam | Integral Skin Foam |

|---|---|---|

| Structure | Fine cellular structure | Dense outer skin with lightweight core |

| Applications | Energy absorption, cushioning | Aesthetics, durability, ergonomic surfaces |

| Customization | Density and hardness adjustments | Textures and colors for design flexibility |

| Resistance | Excellent chemical and environmental resistance | Abrasion, wear, and UV resistance |

Sustainability in Polyurethane Foam Production

The polyurethane industry is increasingly focusing on sustainability, with innovations in recycling and bio-based materials. For example:

- Recycling Microcellular Foam: Used materials can be reprocessed into new products, reducing waste.

- Bio-Based Polyurethane: Renewable raw materials like castor oil are being used to create more eco-friendly foams.

- Smart Foams: Incorporate advanced features like temperature regulation for energy efficiency.

Emirachem is committed to providing sustainable polyurethane solutions that align with global environmental goals. Contact us to learn more about our eco-friendly products.

The Role of Incoterms in Foam Logistics

Efficient logistics are crucial in the polyurethane supply chain, especially for international shipments. Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in global trade.

Commonly Used Incoterms

- FOB (Free on Board): The seller delivers goods to the shipping vessel, with the buyer assuming risk and cost from that point.

- CIF (Cost, Insurance, and Freight): The seller covers the cost, insurance, and freight to the buyer’s port.

- DAP (Delivered at Place): The seller delivers goods directly to the buyer’s location.

At Emirachem, we adhere to Incoterms standards to ensure a seamless and reliable delivery experience.

Why Choose Emirachem for Polyurethane Materials?

- Unmatched Quality: Our materials meet the highest industry standards.

- Global Expertise: With knowledge of Incoterms and international logistics, we ensure hassle-free deliveries worldwide.

- Customization: Tailored solutions to meet your unique application needs.

- Sustainability Commitment: We prioritize eco-friendly practices and products.

For the best polyurethane materials, including solutions for microcellular and integral skin foam, contact Emirachem today and experience unparalleled service and expertise.

Conclusion

Microcellular and integral skin polyurethane foams are transformative materials with applications across diverse industries. Their unique properties, ranging from energy absorption to aesthetic appeal, make them indispensable in modern manufacturing.

If you’re looking to explore the potential of polyurethane foams, reach out to Emirachem. With our expertise, premium-quality materials, and commitment to sustainability, we’re your trusted partner in leveraging the versatility of polyurethane. Let us help you create innovative solutions that stand the test of time.