Everything About Polyurethane Foams

Polyurethane foams are among the most versatile materials in modern manufacturing, with applications ranging from household items to critical industrial components. Their unique properties, coupled with customizable formulations, make them an indispensable part of numerous industries. In this blog, we will delve deep into the types, characteristics, production processes, and wide-ranging applications of polyurethane foams. And remember, for the best quality polyurethane raw materials, contact Emirachem for unmatched expertise and superior products.

What Are Polyurethane Foams?

Polyurethane foams are cellular polymers created through a chemical reaction between polyols and isocyanates, with the inclusion of blowing agents that form the foam structure. This reaction produces a lightweight, durable, and adaptable material that can be customized for various applications. Depending on the formulation and production process, polyurethane foams can be rigid or flexible, each offering unique benefits for specific uses.

Types of Polyurethane Foams

- Flexible Polyurethane Foams

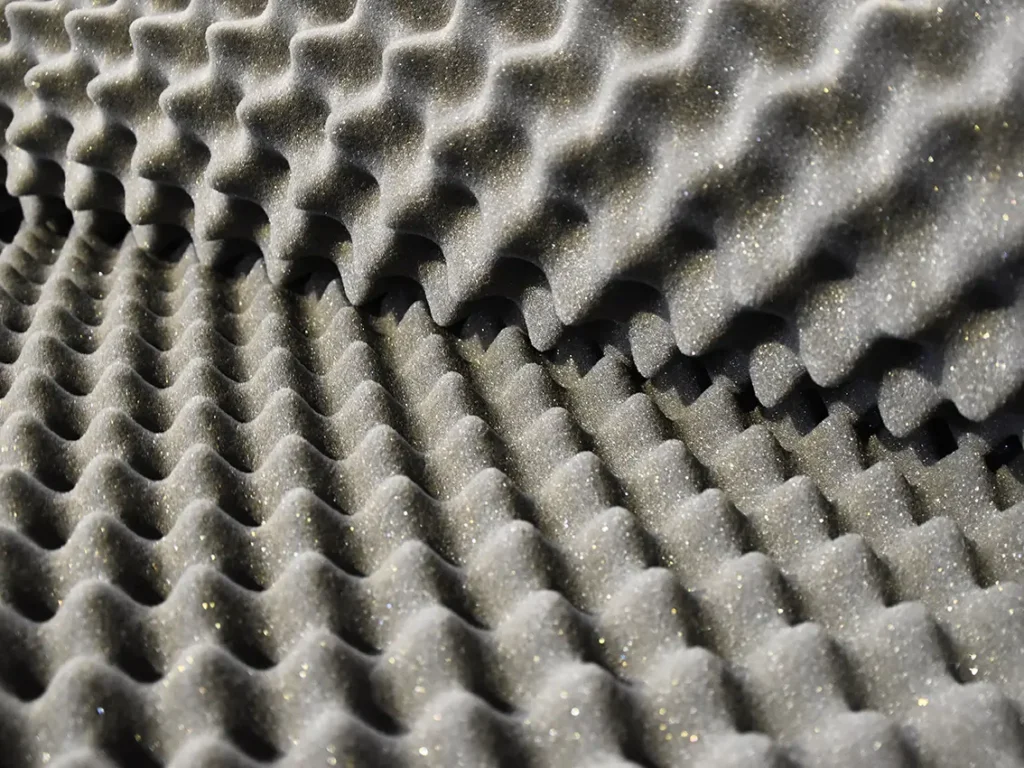

- Characteristics: Flexible polyurethane foams are soft, resilient, and highly compressible. They provide excellent cushioning and comfort, making them a popular choice for furniture, mattresses, and automotive seating.

- Advantages:

- Superior breathability ensures ventilation and moisture control.

- Excellent durability, even under continuous use.

- Customizable firmness levels to suit specific needs.

- Applications:

- Furniture and bedding: Cushions, mattresses, and pillows.

- Automotive: Seats and interior trims.

- Packaging: Shock-absorbing materials for delicate items.

- Rigid Polyurethane Foams

- Characteristics: These foams are dense, durable, and offer outstanding thermal insulation properties. They are ideal for construction and refrigeration industries.

- Advantages:

- Exceptional thermal efficiency reduces energy consumption.

- Moisture resistance prevents mold growth and structural degradation.

- Lightweight yet structurally strong, simplifying installation.

- Applications:

- Construction: Wall and roof insulation, structural panels.

- Refrigeration: Insulation for refrigerators and freezers.

- Automotive: Lightweight body panels and soundproofing materials.

- Spray Polyurethane Foams (SPF)

- Characteristics: SPF is applied as a liquid that expands into a foam, filling gaps and forming a seamless, insulating layer.

- Advantages:

- Quick application and curing process.

- Superior sealing capability eliminates thermal bridging.

- Waterproof and durable for long-term performance.

- Applications:

- Building insulation: Roofs, walls, and attics.

- Industrial tanks and pipes: Prevents heat loss and condensation.

- Integral Skin Foams

- Characteristics: These foams have a dense outer skin and a softer core, offering both durability and comfort.

- Applications:

- Automotive: Steering wheels and dashboards.

- Furniture: Armrests and ergonomic chairs.

How Are Polyurethane Foams Made?

The production of polyurethane foams involves the reaction between polyols and isocyanates in the presence of catalysts, surfactants, and blowing agents.

- Step 1: Formulation: The formulation is adjusted to achieve the desired density, rigidity, and other characteristics.

- Step 2: Mixing: The components are thoroughly mixed to ensure uniform reaction.

- Step 3: Expansion: Blowing agents create gas bubbles, forming the foam structure.

- Step 4: Curing: The foam solidifies as the reaction completes, resulting in the final product.

For consistent quality and performance, the choice of raw materials is critical. Emirachem offers high-quality polyols, isocyanates, and additives to ensure superior foam production.

Applications of Polyurethane Foams

- Construction Industry

- Insulation materials for energy-efficient buildings.

- Spray foam for sealing cracks and gaps.

- Lightweight panels for roofing and walls.

- Automotive Industry

- Seats, armrests, and headrests for enhanced comfort.

- Soundproofing components to reduce noise.

- Lightweight body parts to improve fuel efficiency.

- Furniture and Bedding

- Cushions, mattresses, and pillows for optimal comfort.

- Ergonomic furniture for home and office use.

- Packaging

- Protective foam inserts for electronics and delicate items.

- Custom-molded packaging solutions.

- Medical Applications

- Foam pads for orthopedic devices and prosthetics.

- Medical-grade foams for wound dressings and patient support systems.

Advantages of Polyurethane Foams

- Lightweight: Facilitates ease of handling and reduces transportation costs.

- Durable: Offers long-lasting performance, even under extreme conditions.

- Customizable: Tailored formulations for specific applications.

- Eco-Friendly Options: Availability of bio-based and recyclable polyurethane foams.

At Emirachem, we are committed to providing sustainable and innovative polyurethane solutions to meet the evolving needs of industries worldwide.

Why Choose Emirachem for Polyurethane Foams?

- Premium Quality: Our raw materials meet stringent quality standards.

- Extensive Range: A diverse portfolio of polyols, isocyanates, and additives.

- Expert Guidance: Technical support to optimize your foam production.

- Sustainability: Focus on environmentally friendly products and practices.

Contact Emirachem today for the best polyurethane materials and elevate your manufacturing capabilities.