Understanding Polyurethane Recycling: Challenges, Methods, and Future Opportunities

Polyurethane (PU) is a versatile and widely-used material, employed across numerous industries for its durability, flexibility, and adaptability. From mattresses to insulation panels, adhesives to automotive parts, polyurethane products are indispensable. However, the increasing use of PU has also raised concerns about waste management and environmental impact. Recycling polyurethane offers an effective solution to these challenges, enabling sustainable practices while preserving resources.

This blog delves into the importance of polyurethane recycling, various methods, and emerging innovations. And, if you’re looking for the highest quality polyurethane raw materials for your business, contact Emirachem—your trusted partner in the chemical industry.

Why is Polyurethane Recycling Important?

The chemical structure of polyurethane makes it a durable and long-lasting material. However, these same properties make it challenging to decompose naturally, leading to significant environmental issues. Globally, the rising demand for PU products has resulted in increased waste generation.

Key reasons why polyurethane recycling is critical:

- Environmental Impact: Reducing landfill waste and preventing pollution by minimizing non-biodegradable PU disposal.

- Resource Conservation: Recycling PU materials reduces the reliance on virgin resources like crude oil, used in producing polyols and isocyanates.

- Cost Efficiency: Recycled PU often serves as a cost-effective raw material, providing an economical alternative for manufacturers.

- Sustainability Goals: Recycling aligns with global sustainability efforts to lower greenhouse gas emissions and carbon footprints.

By adopting polyurethane recycling, industries can play a pivotal role in promoting circular economies.

Challenges in Polyurethane Recycling

Recycling polyurethane poses several challenges due to its chemical complexity and diverse applications:

- Cross-linked Structure: Polyurethane’s thermosetting properties make it challenging to melt and reshape, unlike thermoplastics.

- Contamination: PU waste often contains adhesives, coatings, and fillers, making separation and processing more difficult.

- Economic Viability: The cost of recycling PU can be higher than producing virgin materials, deterring some manufacturers.

- Lack of Awareness: Many industries lack knowledge about PU recycling options and their potential benefits.

Despite these hurdles, advancements in technology and increased environmental awareness are driving innovations in polyurethane recycling methods.

Methods of Polyurethane Recycling

Polyurethane recycling methods can be broadly categorized into mechanical recycling, chemical recycling, and energy recovery.

1. Mechanical Recycling

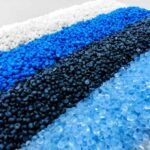

Mechanical recycling involves grinding or shredding polyurethane waste into smaller particles for reuse in various applications.

- Process:

- PU waste is cleaned and processed into powder or granules.

- The material is mixed with virgin polyurethane or other polymers to produce new products.

- Applications:

- Carpet underlays

- Insulation boards

- Composite materials

- Advantages:

- Simple and cost-effective.

- Suitable for large-scale recycling of PU foam.

However, mechanical recycling is primarily used for flexible polyurethane foams and may not be applicable to rigid or coated materials.

2. Chemical Recycling

Chemical recycling breaks down polyurethane into its original raw materials, such as polyols and isocyanates, which can be reused to manufacture new products.

- Techniques:

- Glycolysis: Decomposes PU using glycol, recovering polyols.

- Hydrolysis: Breaks down PU using water and heat to recover polyols and amines.

- Pyrolysis: Heats PU in the absence of oxygen, producing oils and gases.

- Applications:

- High-quality polyols for new PU production.

- Feedstock for other chemical processes.

- Advantages:

- High-quality raw material recovery.

- Applicable to a wide range of PU types.

Chemical recycling is an advanced method that offers greater flexibility but involves higher costs and energy requirements.

3. Energy Recovery

In energy recovery, polyurethane waste is incinerated to generate energy.

- Process:

- PU is burned in waste-to-energy plants, and the heat is converted into electricity or steam.

- Applications:

- Energy generation for industrial or municipal use.

- Advantages:

- Reduces landfill waste.

- Provides an alternative energy source.

However, this method is considered the least sustainable as it contributes to greenhouse gas emissions and doesn’t support circular economy goals.

Innovations in Polyurethane Recycling

With increasing emphasis on sustainability, researchers and industries are exploring innovative recycling methods:

- Microbial Degradation: Leveraging microorganisms to break down PU into biodegradable compounds.

- Bio-based Polyurethanes: Developing PU materials from renewable sources that are easier to recycle.

- Smart PU Materials: Designing polyurethane products with built-in recyclability, enabling easier recovery of raw materials.

- Circular Economy Models: Encouraging manufacturers to adopt closed-loop systems where PU waste is reintegrated into the production cycle.

These advancements offer exciting opportunities to make polyurethane recycling more efficient and scalable.

Where and How to Use Recycled Polyurethane

Recycled polyurethane finds applications across diverse industries:

- Construction:

- Insulation panels made from recycled rigid PU foam.

- Composite materials for roofing and flooring.

- Automotive:

- Seat cushions and padding from recycled flexible PU foam.

- Noise-damping materials.

- Furniture:

- Carpet underlays and cushions from mechanically recycled PU.

- Textiles:

- Bonded PU foam for shoe soles and sportswear.

Recycling polyurethane not only reduces environmental impact but also enhances product affordability and performance. Contact Emirachem for expert solutions and premium raw materials tailored to sustainable manufacturing.

The Role of Emirachem in Polyurethane Recycling

As a leader in polyurethane raw materials, Emirachem is committed to driving sustainability through innovation and quality. Our extensive product portfolio includes high-quality polyols, isocyanates, and additives suitable for recycled polyurethane applications.

Why Choose Emirachem?

- Superior-quality raw materials for recycled PU products.

- Expert guidance on recycling methods and sustainable manufacturing.

- Adherence to international standards for a reliable supply chain.

Contact Emirachem today to explore how we can help you implement sustainable polyurethane solutions.

Conclusion

Polyurethane recycling is a vital step towards reducing waste and creating a sustainable future. Despite challenges, advancements in recycling methods and innovations in PU chemistry are paving the way for a circular economy. Whether through mechanical, chemical, or energy recovery, polyurethane recycling offers immense potential for environmental and economic benefits.

If you’re seeking top-notch raw materials for polyurethane applications or need guidance on sustainable practices, Emirachem is here to help. Together, let’s unlock the full potential of polyurethane while prioritizing sustainability.