What Is Polyol? What Are the Types of Polyol? Where and How to Use?

Polyol is a vital ingredient in the production of polyurethanes, a versatile material used across industries ranging from construction and automotive to medical and consumer goods. Understanding polyols and their types is essential for manufacturers looking to optimize their applications and achieve the desired performance characteristics in their products.

At Emirachem, we provide premium-quality polyols tailored for various applications, ensuring that your polyurethane production meets the highest standards. Contact us today to learn more about our extensive range of polyol offerings.

What Is Polyol?

Polyol is an organic compound containing multiple hydroxyl (-OH) groups, which react with isocyanates to produce polyurethane. This chemical interaction, known as step-growth polymerization, forms a strong and versatile polymer matrix used in a wide range of applications.

Polyols determine the properties of the final polyurethane product, such as flexibility, rigidity, thermal insulation, and abrasion resistance. The choice of polyol plays a critical role in tailoring polyurethane to meet specific requirements.

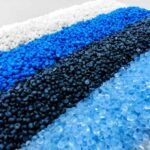

Types of Polyol

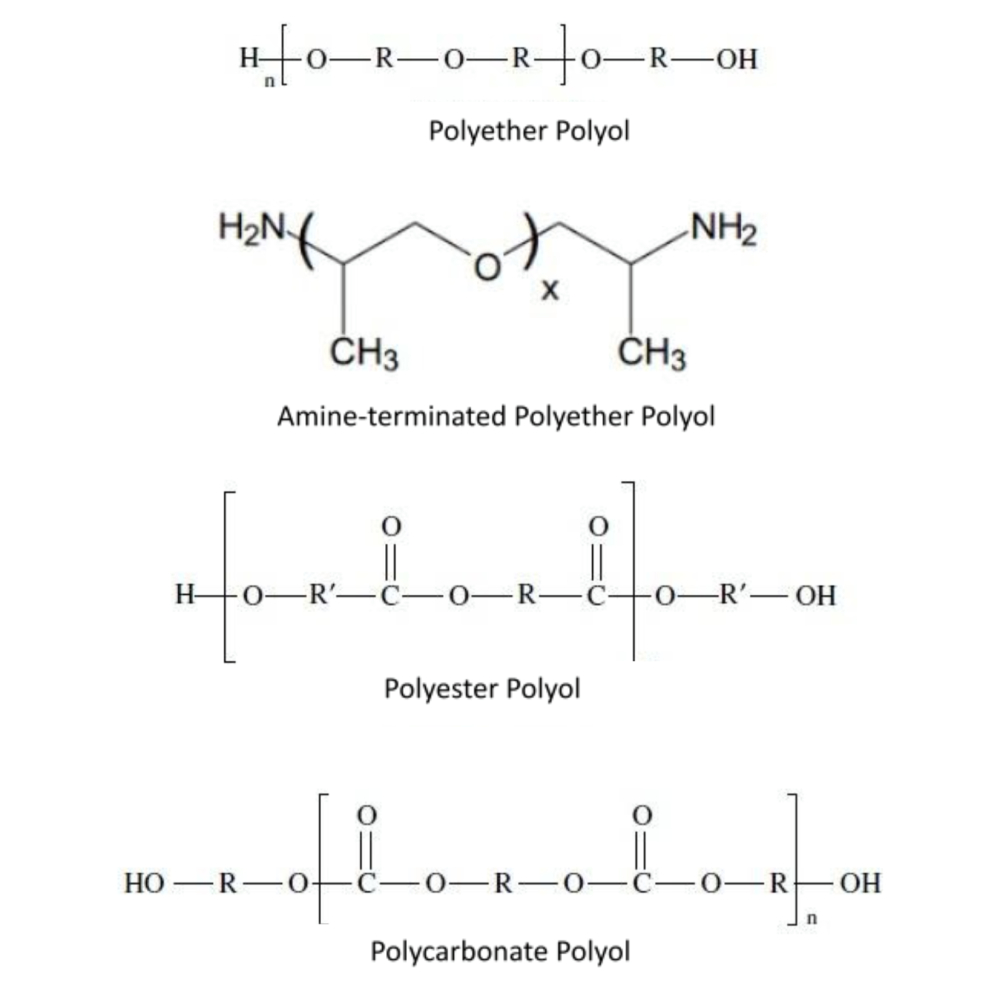

There are two primary categories of polyols used in the production of polyurethane: Polyether Polyols and Polyester Polyols. Each type offers unique properties and benefits suited for different applications.

1. Polyether Polyols

Polyether polyols are produced through the polymerization of alkylene oxides (such as ethylene oxide or propylene oxide) with initiator molecules. They are commonly used in flexible applications due to their exceptional hydrolytic stability and resistance to chemical degradation.

Key Features:

- Excellent flexibility and elasticity

- High resistance to hydrolysis and aging

- Cost-effective and widely available

Applications:

- Flexible Polyurethane Foams: Used in furniture, bedding, and automotive seating for superior cushioning and comfort.

- Adhesives and Sealants: Provides strong bonding and sealing capabilities in industrial and construction applications.

- Elastomers: Offers high elasticity and durability for applications like industrial belts and seals.

2. Polyester Polyols

Polyester polyols are formed by reacting dibasic acids with diols. They are known for their higher tensile strength, thermal stability, and resistance to abrasion, making them ideal for rigid and high-performance applications.

Key Features:

- High mechanical strength and durability

- Superior thermal and chemical resistance

- Ideal for demanding environments

Applications:

- Rigid Polyurethane Foams: Used in construction for thermal insulation and structural support.

- Coatings: Provides excellent protection and durability for surfaces exposed to harsh conditions.

- Elastomers: Commonly used in automotive and industrial components that require high performance and resilience.

Where to Use Polyols?

Polyols are essential in numerous industries due to their ability to customize polyurethane properties. Below are some key applications where polyols are indispensable:

1. Construction Industry

Polyols are widely used in rigid polyurethane foams, which are critical for thermal insulation in buildings, pipelines, and refrigeration systems. Their lightweight and moisture-resistant properties make them ideal for sustainable construction.

2. Automotive Industry

Flexible polyurethane foams, derived from polyols, are used in car seats, dashboards, and interior trims. These foams enhance comfort, reduce noise, and improve energy absorption in vehicles.

3. Furniture and Bedding

Polyether polyols are used to create flexible foams that provide comfort and durability in mattresses, sofas, and cushions.

4. Coatings and Adhesives

Polyols are integral to producing polyurethane coatings and adhesives, offering superior protection, bonding, and flexibility for industrial and consumer applications.

5. Footwear

Polyurethane elastomers made from polyols are used in shoe soles for their lightweight, durable, and abrasion-resistant properties.

How to Use Polyols?

Polyols are mixed with isocyanates in specific ratios to produce polyurethane. The choice of polyol, along with the addition of catalysts, blowing agents, and other additives, allows manufacturers to create customized formulations suited to their needs.

Factors to Consider When Using Polyols:

- Application Requirements: Choose the appropriate type of polyol (polyether or polyester) based on the desired properties.

- Additives and Catalysts: Optimize the formulation with the right additives to enhance performance.

- Processing Conditions: Ensure accurate mixing and processing to achieve consistent quality.

At Emirachem, we provide technical expertise and high-quality polyols to help you achieve the best results in your polyurethane production.

Why Choose Emirachem for Polyols?

- High-Quality Raw Materials: Our polyols meet stringent industry standards to ensure reliable performance.

- Diverse Product Range: We offer a comprehensive selection of polyether and polyester polyols for various applications.

- Expert Support: Our team provides tailored solutions to meet your specific requirements.

- Global Reach: With a strong supply chain and adherence to Incoterms standards, we ensure seamless delivery worldwide.

Contact Emirachem today to discover the best polyol solutions for your business.

Conclusion

Polyols are the backbone of polyurethane production, determining the properties and performance of the final product. Whether you’re creating flexible foams for comfort or rigid foams for insulation, choosing the right polyol is essential for success.

At Emirachem, we are committed to providing top-quality polyols and expert support to help you meet your manufacturing goals. Reach out to us today and experience the difference in quality and service. Let us be your trusted partner in the world of polyurethane chemistry!